Our Machining Process

Every project follows a proven system built on precision, communication, and consistency.

- Home

- Our Process

Our Proven Process

- Full Turnkey Capabilities

- ISO Certified Quality System

- 50+ Years of Machining Experience

- Consistent On-Time Delivery

- Advanced Inspection

- Material Traceability

1 +

Years Experience

1 +

Precision Machines

± 1

Tolerance

1

Sq. Foot Facility

Step 1: Inquiry and Review

Each project begins with a detailed review by our precision machining experts. We analyze prints, tolerances, and materials to ensure the most efficient and accurate manufacturing process. As a full-service CNC machine shop, we work directly with engineers and buyers to identify potential improvements, optimize manufacturability, and confirm delivery requirements before production begins.

Step 2: Production Review and Planning

Before machining begins, our production team performs a complete job review to plan every step of the manufacturing process. We assign each operation to the ideal machine, schedule run times based on efficiency, and ensure tooling, fixtures, and inspection plans are prepared ahead of time. This planning phase eliminates downtime and guarantees that every job runs smoothly through our CNC lathes, mills, and grinders. Our goal is to align precision, speed, and quality — every time.

Step 3: Material Selection & Certified Sourcing

Every job begins with a careful evaluation of the material requirements. As a leading precision machine shop in Anaheim, we source all materials from trusted, certified suppliers to ensure full traceability, consistent quality, and compliance with customer specifications. Whether your project requires stainless steel, aluminum, specialty alloys, plastics, or bar stock for CNC lathe work, our team selects the ideal material grade and form to support accurate machining and cost-efficient production.

Step 4: Programming and Set up

Our programming team uses advanced CAD/CAM software to generate precise toolpaths and machining simulations before production begins. Each setup is engineered for accuracy and repeatability, ensuring that critical dimensions and surface finishes are achieved consistently. Tooling, fixtures, and offsets are verified by our lead machinists so every CNC lathe, mill, or grinder is ready to run efficiently from the first part to the last.

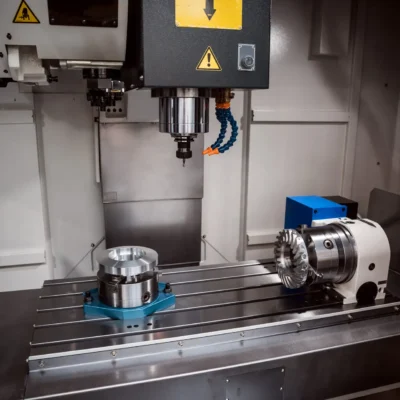

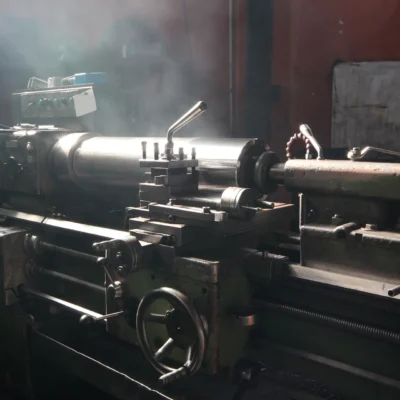

Step 5: Machining and Production

Once the job is on the floor, our machinists bring the plan to life. Using state-of-the-art CNC lathes, mills, and grinders, each part is machined to exact specifications. In-process inspections are performed at every stage to verify accuracy and maintain consistency across the full production run. Our team takes pride in craftsmanship — delivering precision components that meet the tightest tolerances and highest quality standards.

Step 6: In-Process Quality Checks

Quality is built into every stage of production at Turret Lathe Specialists. Throughout machining, our team performs detailed in-process quality checks to verify critical dimensions, surface finishes, and geometric features before the part ever reaches final inspection. Using calibrated tools, precision gauges, and real-time measurement techniques, we ensure accuracy at each setup and operation.

Step 7: Outside Processing Coordination

Many precision-machined parts require additional processes beyond CNC turning and milling, and our team manages every step for you. As a full-service precision machine shop in Anaheim, we coordinate all outside processing—including heat treat, plating, anodizing, grinding, coating, passivation, and specialty finishes—through our network of certified, reliable vendors. We handle scheduling, logistics, quality verification, and documentation to ensure each part meets your exact specifications before returning to our facility for final inspection

Step 8: Quality Control and Inspection

At Turret Lathe Specialists, quality isn’t a final step — it’s the foundation of everything we do. As a leading precision machine shop in Anaheim, our inspection process is built around accuracy, traceability, and consistency from the moment material arrives to the moment finished parts leave our facility. Every component we produce goes through a series of in-process and final inspections using calibrated equipment, industry-standard measurement tools, and advanced metrology practices designed to verify even the most demanding requirements.

Our inspection department utilizes precision instruments such as micrometers, calipers, bore gauges, height gauges, and surface plates, along with advanced CMM capabilities for high-accuracy dimensional verification. Our Zeiss coordinate measuring machine enables fully automated, hands-free inspection cycles with detailed reporting, ensuring that every critical feature is measured, recorded, and validated.

Step 9: Packaging and Delivery

After inspection, parts are cleaned, labeled, and packaged for protection during transport. We coordinate delivery to meet your schedule — whether that’s same-day local delivery or custom export packaging for international shipments. Our logistics process is built to maintain part integrity and on-time performance from our floor to your door.

A Process You Can Count On

At Turret Lathe Specialists, our 50+ years of machining experience have taught us that great parts don’t happen by accident — they’re the result of a proven, repeatable process backed by skilled people, dependable systems, and true accountability. Every step in our workflow is designed to give you confidence: certified materials, thoughtful programming, precise machining, in-process inspection, fully managed outside processing, and a rigorous final quality check before anything leaves our Anaheim facility.

- Full Turnkey Capabilities

- ISO Certified Quality System

- 50+ Years of Machining Experience

- Consistent On-Time Delivery

Submit your Quote Today

Turret Lathe Specialists is a trusted CNC machine shop in Anaheim, CA, serving aerospace, commercial, cryogenic, energy, and defense industries. Use the form below to request a CNC machining quote for your part or assembly. Attach your drawings, and include as much detail as possible — our team will respond within one business day.

Explore our Services

Recent Blog Posts

5-Axis CNC Machining with the Haas UMC-750

Stay Connected

Subscribe to our newsletter for behind-the-scenes updates, machining tips, and company news.Our Location

Turret Lathe Specialists

Anaheim, CA 92805