Let’s Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Grinding Capabilities:

With the acquisition of Active Grinding, Inc., Turret Lathe Specialists has expanded our in-house capabilities to include world-class precision grinding. Backed by over 60 years of grinding expertise, we now deliver a full range of ID, OD, centerless, surface and thread grinding, — all under one roof

✓ 12 Advanced Grinders – Equipped with the latest technology for maximum accuracy, repeatability, and efficiency.

✓ ID Grinding – CNC and Manual, Bores up to 36” depth and 30” swing with exceptional accuracy.

✓ OD Grinding – CNC and Manual, Up to 72” length, 12” diameter

✓ Tolerances – Capable of holding ±0.00005” on precision-critical dimensions.

✓ Surface Grinding – Up to 12” x 24” x 8” for flatness and finish-critical components

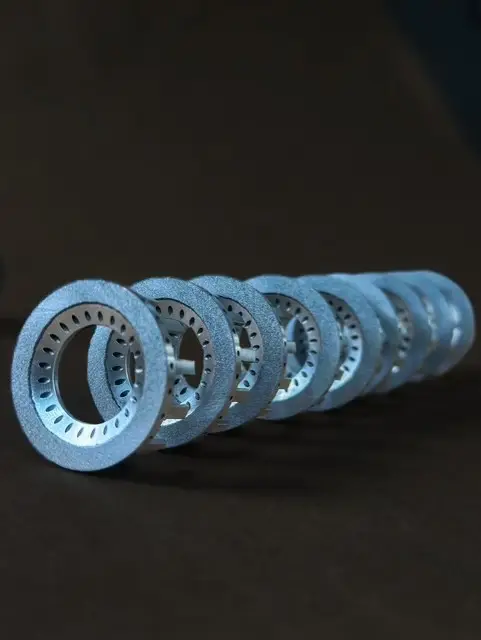

✓ Centerless Grinding – High volume runs with repeatability and efficiency

✓ Thread Grinding – Precision thread profiles with tight tolerances and superior finish.

✓ Quality Assurance – In-process inspection and CMM verification ensure every component meets exact specifications.

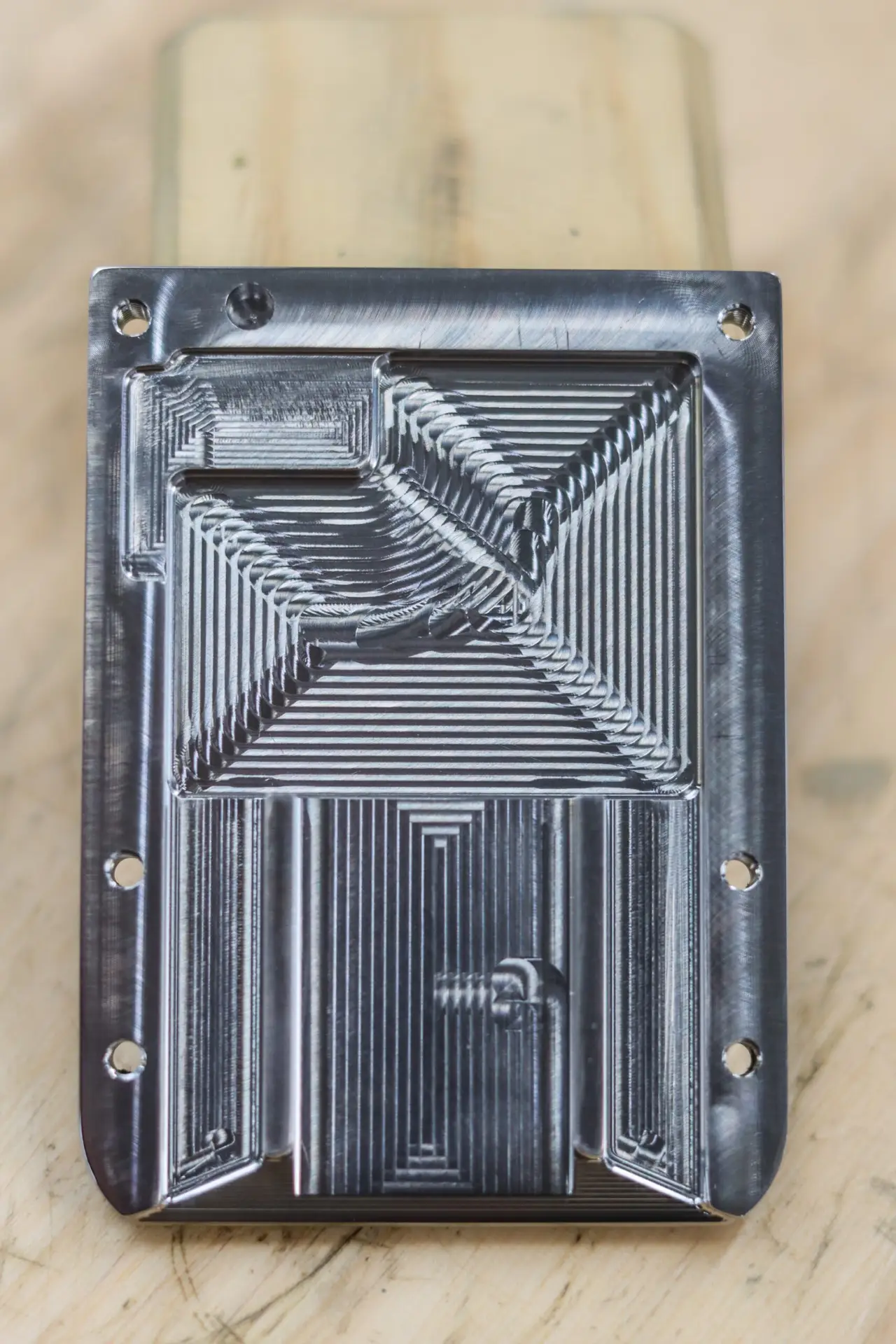

Our New CNC ID Grinder

Our new Supertec CNC ID Grinder delivers ultra-tight tolerances with flawless repeatability. Designed for complex internal features, it streamlines setups and shortens lead times giving customers faster, more precise results.

- Flawless repeatability and surface finish

- Blind holes, through holes & multi-step profiles

- Tolerances down to ±0.00005"

- Faster Lead Times for ID Grinding

Our Grinding Expertise

At Turret Lathe Specialists, we combine the efficiency of CNC machining with the craftsmanship of manual expertise to deliver precision parts for demanding industries. Whether it’s high-volume production or complex, one-off projects, our team brings decades of experience to every component we machine.

- Cylindrical & Surface Grinding – High-accuracy OD, ID, and surface grinding for shafts, sleeves, housings, and critical sealing surfaces.

- Complex Components – Experience with tapers on shafts, impellers, cylinders, pistons, wheels, castings, and other ultra high-precision geometries.

- Complementary Services – Integrated with our CNC milling and turning departments to provide turnkey manufacturing solutions.

12+ grinders | ±0.00005” | cnc and manual

We excel in grinding shafts, cylinders, sleeves, housings, pistons, wheels, impellers, inducers, and complex castings — delivering the accuracy and surface finishes critical for high-performance applications.

A combination of advanced CNC grinders and manual expertise allows us to handle everything from high-volume production to one-off legacy parts.

Our grinding department works hand-in-hand with milling and turning to deliver complete, ready-to-use components — reducing lead times and eliminating the need for multiple vendors.

SUPERTEC CNC ID GRINDER

Our new Supertec CNC ID Grinder expands our precision capabilities with ultra-tight tolerances. This investment ensures we can support the most demanding applications with speed, accuracy, and confidence.

- Ultra-tight tolerances down to ±0.00005"

- Precision repeatability with closed-loop feedback

- Capable of blind holes, through holes, and multi-step profiles in a single setup

Grinding FAQs

Our CNC and manual grinding departments routinely hold tolerances as tight as ±0.00005", delivering the accuracy required for critical applications.

We use documented setups, custom fixtures, and in-process inspection to ensure parts remain consistent from the first run to the thousandth.

Our grinding department works hand-in-hand with milling and turning, allowing us to deliver turnkey components with shorter lead times and reduced outsourcing.