Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

875 S. Rose Place, Anaheim CA 92805

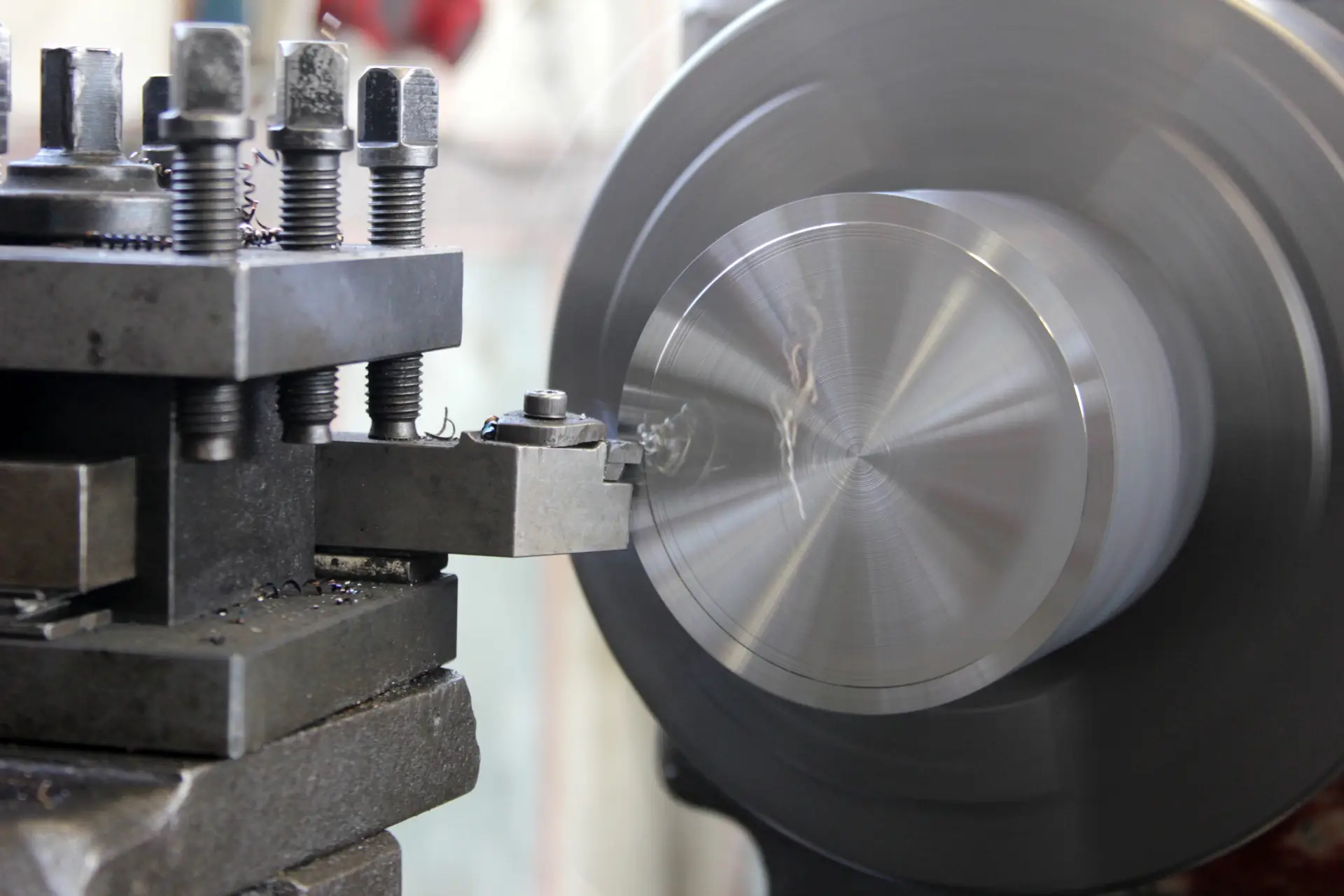

Turning Capabilities

Turret Lathe Specialists was built on lathe work — it’s in our name and in our DNA. With decades of expertise in precision turning, we specialize in producing high-tolerance shafts, housings, and cylindrical components for industries where reliability is everything. From prototype runs to long-term production, our turning department delivers the accuracy and consistency that established our reputation as true lathe specialists.

✓ 14 Advanced CNC Turning Centers – Equipped with the latest technology for maximum accuracy, repeatability, and efficiency.

✓ Size Capacity – Turning operations for parts up to Ø55” in diameter and 200” in length.

✓ Live Tooling & Sub-Spindles – Advanced multi-axis lathes allow for milling, drilling, and complex features in a single setup.

✓ Tolerances – Capable of holding ±0.0002” on precision-critical dimensions.

✓ Material Expertise – Skilled in machining stainless steel, titanium, Inconel, Monel, aluminum, plastics, and specialty alloys.

✓ Industries Served – Supporting renewable energy, aerospace, commercial, oil & gas, defense, cryogenics, and more.

✓ Production Flexibility – From one-off prototypes to full-scale production runs, we tailor our processes to meet your needs efficiently.

✓ Quality Assurance – In-process inspection and CMM verification ensure every component meets exact specifications.

14+ Lathes | 55” Dia x 200” | ±0.0002”

OUR TURNING EXPERTISE

At Turret Lathe Specialists, turning is where it all began. With both CNC and manual departments, we have the flexibility to handle everything from complex, high-precision components to simpler jobs that demand craftsmanship and efficiency. Our team’s experience and diverse equipment allow us to deliver dependable results across a wide range of part types and industries.

- Shafts & Cylindrical Components – Precision-turned parts for pumps, aerospace, and critical rotating equipment.

- Housings, Sleeves & Bushings – Tight-tolerance components that ensure proper fit, sealing, and performance.

- Specialty & Legacy Parts – One-off, prototype, and manual lathe work for custom or hard-to-source components.

Shafts, impellers, cylinders, sleeves, bushings, pistons, housings, wheels, inducers, and complex castings — all produced with precision and repeatability.

Turning operations ranging from small, intricate components to oversized parts up to Ø55” × 200” long.

Our journeymen machinists combine hands-on craftsmanship with advanced CNC technology to deliver both complex production and one-off legacy parts.

Turning FAQ's

Our CNC Turning Department specializes in producing high-precision cylindrical components, complex geometries, and tight-tolerance parts for critical industries.

We machine shafts, impellers, cylinders, sleeves, bushings, pistons, housings, wheels, inducers, and complex castings — from prototypes to full production.

Our CNC lathes handle parts up to Ø55” in diameter and 200” in length, giving us flexibility for both small and oversized components.

Yes. Alongside our CNC department, we maintain a manual lathe team for one-off jobs, legacy components, and specialized work that benefits from hands-on craftsmanship.

We regularly hold tolerances down to ±0.0002” on critical features, with in-process inspection and CMM verification for quality assurance.

Our machinists are skilled in stainless steel, aluminum, titanium, Inconel, Monel, bronze, plastics, and other specialty alloys and exotic materials.