Let’s Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

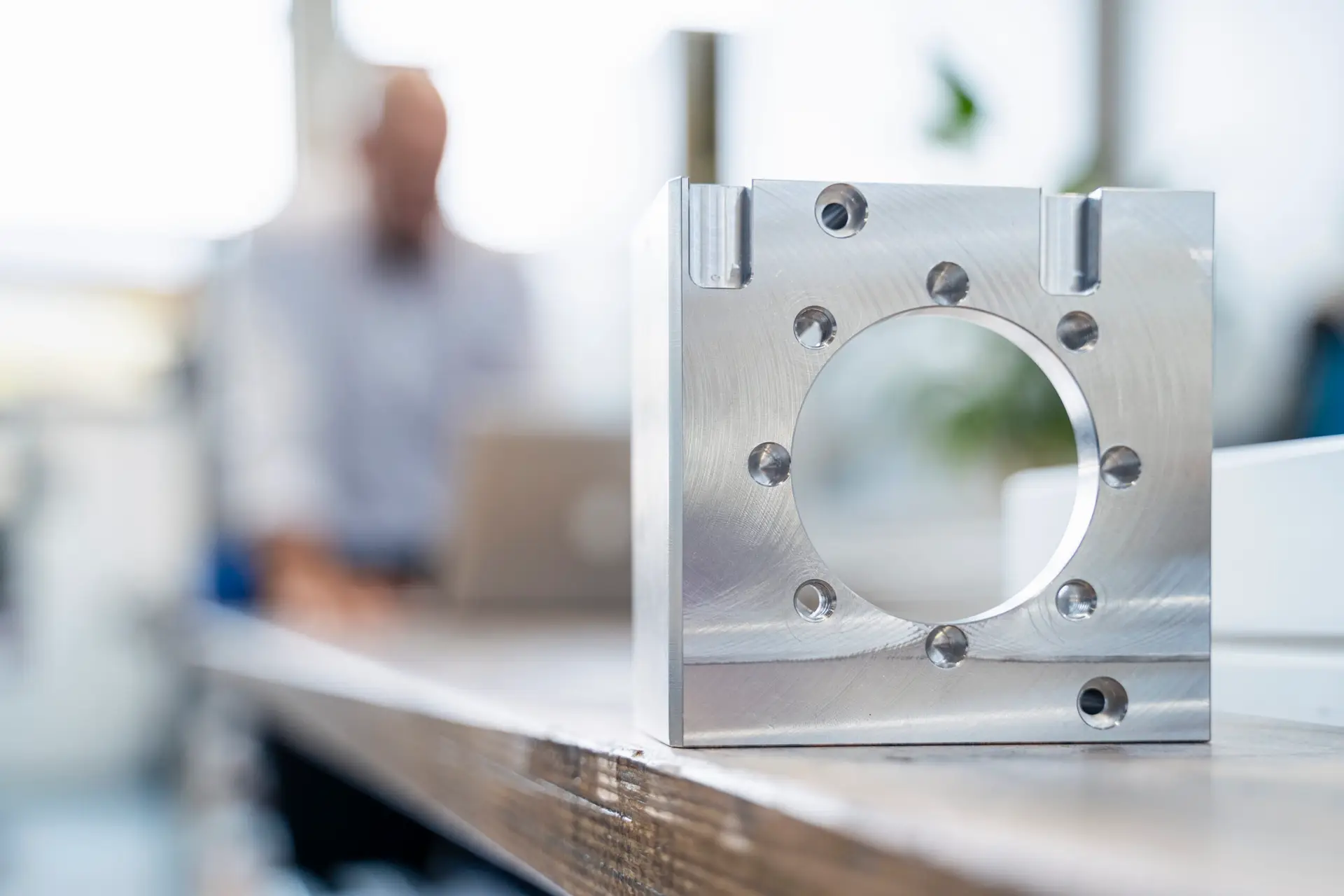

Specialty Machining Services:

At Turret Lathe Specialists, we know that not every project fits neatly into production runs or standard machining. That’s why we maintain a dedicated Specialty Machining Department—equipped with manual lathes, mills, and staffed by highly skilled machinists—focused on the one-off, custom, and complex jobs that set us apart. These “extra” capabilities are where our decades of craftsmanship truly shine.

Prototyping and Product Development

From first-article samples to proof-of-concept builds, our machinists work side by side with engineers to transform ideas into tangible parts. We specialize in fast-turn prototypes, offering flexibility and creativity without sacrificing the precision you expect from production machining.

Tooling & Custom Fixtures

Our in-house team designs and builds custom tooling, jigs, and fixtures that improve repeatability, reduce setup time, and optimize the overall machining process. This capability not only supports our own shop floor but also adds value to customers who require one-of-a-kind solutions for their assemblies and production lines.

Repair & Rework Services

Sometimes it’s more cost-effective to repair or rework a part than to start from scratch. Our manual department excels at precision repairs, salvaging valuable components, modifying existing parts, and restoring critical features to spec. This service has helped many customers reduce downtime and avoid costly replacements.

Reverse Engineering

When prints or CAD models aren’t available, our team provides reverse engineering services. Using advanced measurement tools and decades of hands-on expertise, we recreate accurate part geometry and develop manufacturable models that can be used for ongoing production, spares, or redesign.

Skilled Manual Machining

When prints or CAD models aren’t available, our team provides reverse engineering services. Using advanced measurement tools and decades of hands-on expertise, we recreate accurate part geometry and develop manufacturable models that can be used for ongoing production, spares, or redesign.